When Shark Seating founder Paul Zwaan first encountered marine suspension seating, one thing stood out: the price. These systems were expensive, often out of reach for everyday boaties and even many professionals. Yet, the need was undeniable. Anyone spending time offshore or regularly punching through waves is exposed to impacts that the human body simply isn’t built for. Telling boaters they can have a boat, but if they want a safer, smoother ride they’ll have to pay a premium, felt like saying, “Sure, your car comes with wheels, but airbags? That’s extra.”

This wasn’t just about filling a gap in the market. It was about changing the way people experience boating. Protecting backs, joints, and brains from the hidden toll of constant wave impacts.

Why Suspension Seating Matters

Comfort isn’t the sole focus of suspension seating; it’s about safety and long-term health. Multiple studies have shown that repeated wave impacts can cause spinal injuries, joint pain, cognitive fatigue, slower reaction times, and more. These effects are serious, especially for commercial crews and serious offshore anglers who clock long hours in rough seas. And while many don’t realize the damage is happening, the consequences can be lasting.

References at end of article

What Had to Be Achieved

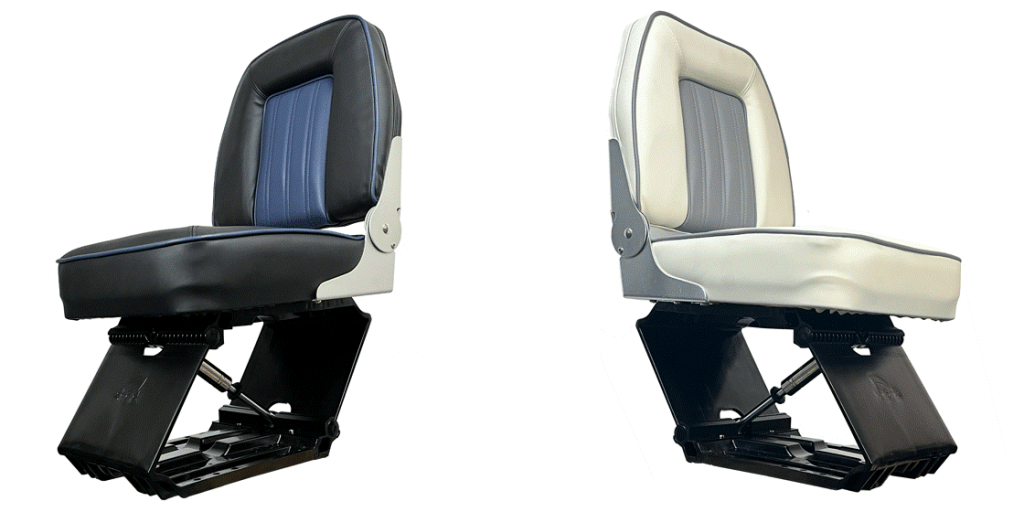

To solve this problem properly, Shark’s suspension seats couldn’t just match what existed, they had to exceed standards. The key design goals were clear:

- Affordable – so more boaters could benefit from the technology.

- Lightweight – keeping boats faster, more efficient, and easier to handle.

- Customizable – with accessories to suit a wide range of vessels and industries.

- Simple – corrosion-resistant, easy to maintain and service.

- Capable – handling heavy wave impacts while still smoothing out small chop.

- Strong yet flexible – durable enough to survive extreme punishment.

- Long suspension travel – maximizing the protective range of motion.

These weren’t just nice-to-have elements, they were essential. Achieving them all meant Shark had to rethink every part of the seat, from the inside out.

Enter FLEXANITE®

At the core of Shark’s innovation is a material called FLEXANITE, a custom plastic composite engineered specifically for marine suspension. It’s strong, flexible, UV-treated, weatherproof, and designed to work in perfect harmony with the shock absorber. While the final product appears sleek and simple, it’s the result of countless hours of development and experimentation.

The Art (and Pain) of Injection Molding

Plastic was a bold choice. Injection molding in particular demands serious precision and marine environments don’t forgive mistakes. When a hot part comes out of the mold, it’s still soft, almost gooey. As it cools, it moves, bends, and warps. This meant Shark couldn’t just design the ideal part, they had to design the ideal post-movement part. The tools used to shape FLEXANITE cost tens of thousands of dollars and had to be made wrong (dimensionally) in order to come out right after cooling.

It’s a far cry from working with metal, where things stay where you put them. Plastic has a mind of its own.

Innovation with Intent

To truly solve the affordability issue, Shark had to get clever. Once the costly tooling was done and the FLEXANITE material perfected, production became significantly more cost-effective than fabricating traditional metal suspension. One of the smartest moves? Designing the leaf and clamp to be the same part, mirrored on each side. That’s one mold, two uses, keeping costs down while maintaining balance and performance.

This kind of design isn’t just problem-solving, it’s inventing. There was no playbook to follow. FLEX-based marine seating hadn’t been done before. Every challenge required a custom solution, from material blends to mechanical geometry. While injection molding is nothing new, applying it in this way for high-impact, high-abuse, saltwater environments was unexplored territory.

Pioneering a Better Ride

Shark Seating didn’t want to do what everyone else was doing. If they had, they wouldn’t have solved the problem. By forging their own path, taking risks, failing, learning, and iterating, they built something that didn’t just match the competition, but reshaped expectations entirely.

Boating shouldn’t hurt. And thanks to smart design, bold material choices, and a bit of Kiwi tenacity, it doesn’t have to.

References:

Breslin, S. (2020, August). Small boat operators are overexposed to whole-body vibration. U.S. Naval Institute. https://www.usni.org/magazines/proceedings/2020/august/small-boat-operators-are-overexposed-whole-body-vibration

Professional Mariner Staff. (2012, July 9). Vibration aboard high-speed boats can cause serious health problems. Professional Mariner. https://professionalmariner.com/vibration-aboard-high-speed-boats-can-cause-serious-health-problems/

Sargeant, M., McGrath, B., & Usher, L. (2008). Seating type and cognitive performance after 3 hours’ travel by high-speed boat in sea states 2–3. Journal of Cognitive Ergonomics, 12(3), 175–183. https://www.researchgate.net/publication/23962773_Seating_Type_and_Cognitive_Performance_After_3_Hours_Travel_by_High-Speed_Boat_in_Sea_States_2-3